ITEM SPECIFICS

-

Brand

Model MIAMUnbranded

-

origin

Republic of Korea

-

Size(Capacity)

PRODUCT DESCRIPTION

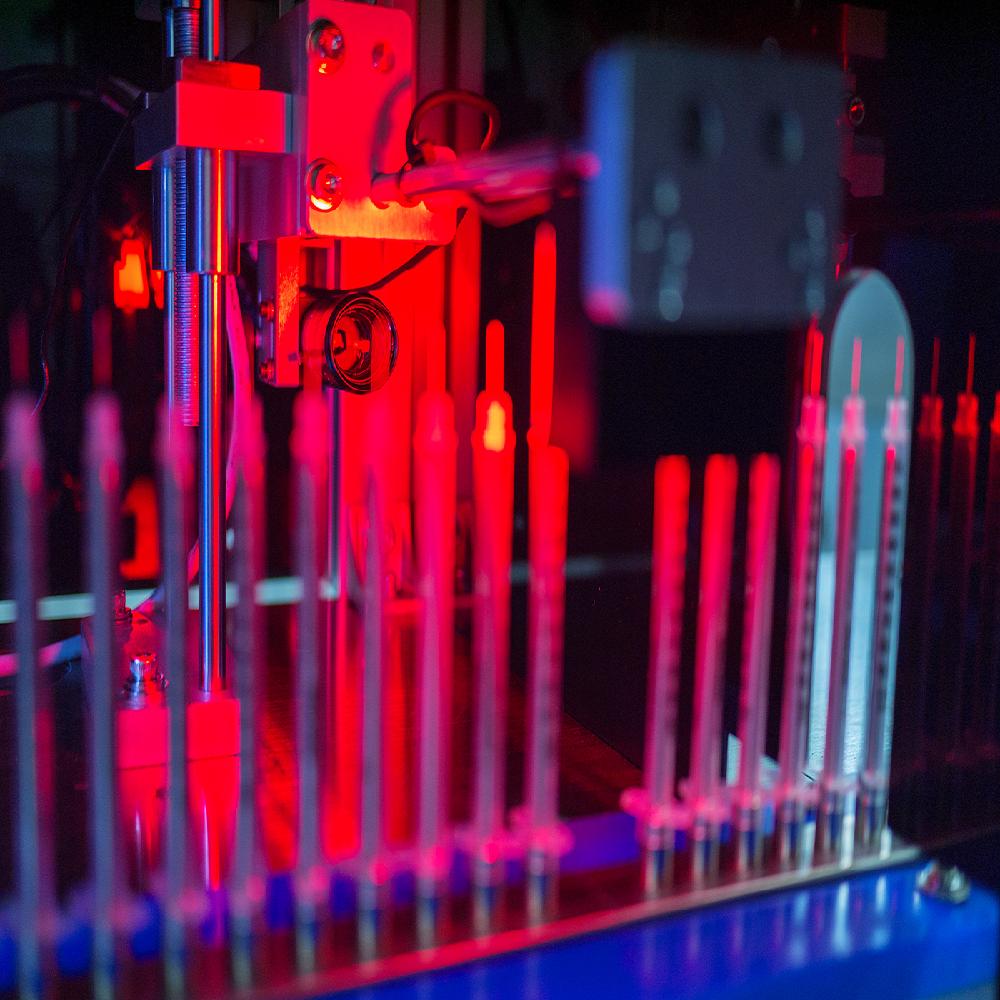

Introduction

What are they?

Because of increase in adult disease, the number of diabetic is on the rise. In order to meet this market needs you need effective insulin syringe assembly line with high productivities.

• Body x-frame : made with highest quality robust raw materials. Body x-frame is really important for durability and life span

• Standardized products : We use parts and products fromworld famous companies only. You can get the parts easily everywhere in the world.

• Yield percentage : We boast high yield percentage. It is about 95% or more.

• 0.3ml : 15,000pcs/hour

• 0.5ml : 15,000pcs/hour

• 1ml : 15,000pcs/hour

* Productioncapacity depends on plastic parts qualities and operator’s technical skills.

How do they work?

Automatic insulin syringe line is combined assembly system of printing machine and assembly machine. Firstly barrels are supplied to the printing process. Secondly the barrels are assembled with cannulas and then they are passed though drying furnace and camera inspection zone. Lastly all the parts such as needle caps, plungers and plunger caps are assembled. On request we can add welding device at the connection part between needle caps and barrels to check whether it is a new one.

On request CE certificate is available.

PAYMENTS DETAILS

- Telegraphic Transfer : T/T

- Name : Manager

SHIPPING

- , 충청남도,

-

- Business Type :

- Manufacturer

-

- Main Product :

-

- Established :

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Please enter the text on the left image to prevent automatic input.

0 / 4000

CUSTOMER REVIEWS (0)

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

SILVER

SILVER

- Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★